Big-Mach Vacuum Clamp Kit (Large)

A True Time Saver – No More Clamps

| Ships From: |  MPOWER Canada – Ontario MPOWER Canada – Ontario |

|---|---|

| Currency: | Prices shown in $ Canadian Dollars |

| Returns: | Returnable within 30 days of receipt |

| Payment: | Secure transaction |

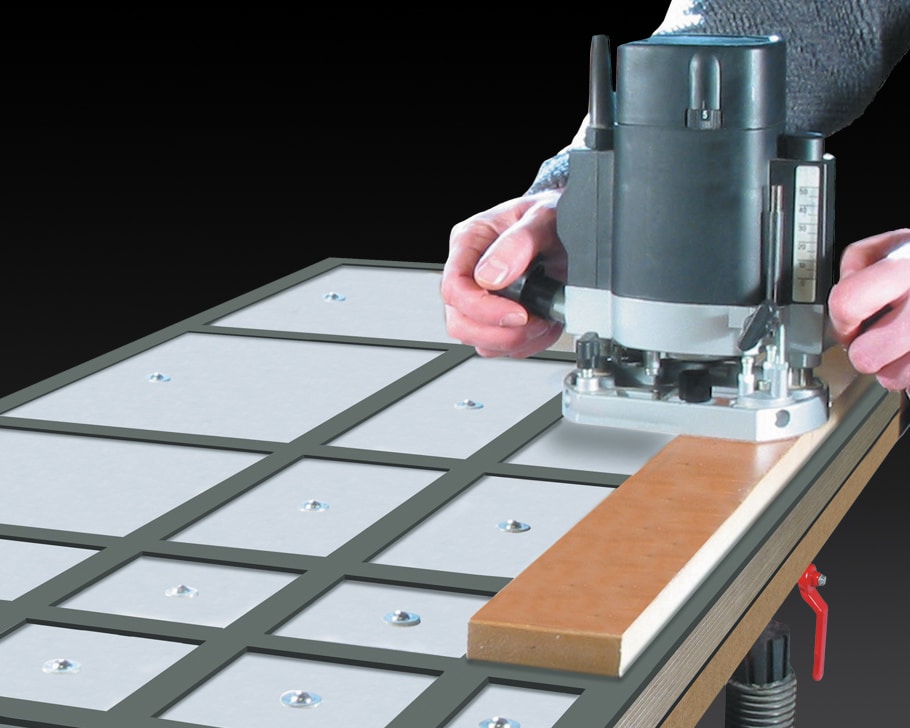

The Big-Mach Vacuum Clamp Kit provides all the essential components for the construction of an industrial sized vacuum hold down table and power tool platform for clamp-free, obstruction free woodworking operations. It is based on the proven vacuum clamping work bed ‘Mach’ family technology and is ideally suited to small, medium and large workshops where industrial sized vacuum clamping is required at a very affordable price.

The unique feature of vacuum clamping work beds over more traditional methods is the speed, reliability and ease they bring to securing and holding down boards, components and delicate workpieces, whether small, medium or large (100mm² to 2440mm²). Place the component over one of the vacuum cells, turn on the vacuum control tap, press the component down lightly to activate the vacuum cell ball-valve and the piece is now firmly held ready to be worked on. No clamping, no cramping, no taping, no tacking, no gluing, no bench dogs or flakey router mats. Mach vacuum clamping work beds offer firm robust grip and hold whilst removing all that time spent undoing and resetting clamps and cramps so you can get on with the real job.

Hold large components

The Big-Mach dimensions are 1020 x 520mm, but it is capable of holding very large components such as standard 8’x4′ (2440mm x 1220mm) and 10’x5′ boards

Versitile Mounting

It has a sealed internal vacuum chamber meaning it is a stand-alone system that can be mounted and moved where necessary whether in the workshop or attached to a portable workbench ‘on-site’ at a construction project. The Big Mach when constructed has a number of mounting points and options offering you the end user the greatest degree of flexibility to use this vacuum bed as you see fit.

Multiple Vacuum Sources

The Big Mach can be run from a number of vacuum sources such as a standard domestic 1000watt cylinder vacuum cleaner, a workshop extractor, a dedicated vacuum pump or a venturi attached to a workshop air-compressor or air-line.

Various Workpeice Sizes

The clamping bed comprises of a matrix of vacuum cells of graduated size. This allows various workpiece sizes to be held. Each vacuum cell comprises of a pressure-activated ball valve which controls air-flow to the cell. There is also a surrounding gasket wall of rubber sponge neoprene polymer material which seals the cell against the workpiece creating a vacuum seal. Once air has been evacuated from the cell the vacuum clamp forms a very strong lateral hold on the workpiece. This means it is a very effective clamp for obstruction free and clamp free routing (single pass clamp free all edge routing), belt sanding, planning, biscuiting, panel trimming and use with all hand tools.

Repetition

Because vacuum hold work beds are clamp and cramp free they are perfect for batch processing and production of repetitive component shapes using simple vacuum templates. Being able to work obstruction free takes the hassle out of the work. A simple turn of the Vacuum Control Tap releases the seal and the component can be lifted straight off the work bed ready for the next piece. The Tap in turned back on and the new board or component is firmly clamped ready to be routed, sanded or what ever takes your fancy.

Mach Vacuum Instruction Manual Pg 2

Mach Vacuum Instruction Manual Pg 3

Mach Vacuum Instruction Manual Pg 4

Mach Vacuum Instruction Manual Pg 5

Mach Vacuum Instruction Manual Pg 6

Mach Vacuum Instruction Manual Pg 7

Mach Vacuum Instruction Manual Pg 8

Mach Vacuum Instruction Manual Pg 9

Mach Vacuum Instruction Manual Pg 10

1x vacuum control tap assembly with tapered hose adapter

20x pressure activated ball valves

2x 2.0 metres of top gasket material

4x 2.0 metres of bottom gasket material

1x 1/1-scale cutting guide template

1x U-Mach construction guide

1x Mini Mach instruction manual

You will require some suitable material (25mm x MDF, fiberboard, marine multi ply) for the platen and a basic woodworking tool kit to help you build either a Mini Mach or a custom vacuum jig work bed. You will also need a vacuuM.POWER source (minimum 500 watt vacuum cleaner/shop extractor or industrial vacuum pump with a minimum rating of 6 cubic metres per hour)